PRODUCTION ADVANTAGE

We specialize in packaging machine for 20 years, we meet the needs of customers of various specifications and best-selling in world market by stable quality and factory price.

SERVICE ADVANTAGE

We have a 10-year marketing team, one to one after-sales service for all customers.

DELIVERY ADVANTAGE

our machines are very popular at home and abroad, we have some standard equipment in stock, customize machine normally delivery in advance, we have our own professional transport chain.

Related Products

More items about food cartoning machine

We Have The Best Solutions for Your Business

Wenzhou Tuoyi Machinery Co., Ltd. is a technological machinery enterprise integrating R&D, manufacturing and sales. ave a group of experienced machinery R&D and sales teams.

Our main products are capping machine, cartoning machine, cellophane wrapping machine, film packaging machine, film wrapping machine, food cartoning machine, horizontal cartoning machine, labeling machine, liquid filling machine, overwrapping machine, pharmaceutical cartoning machine, sealing machine, shrink packaging machine, shrink wrap machine, shrink wrapping machine, sticker labeling machine, wine labeling machine,. If you are interested in that, please contact us for more information.

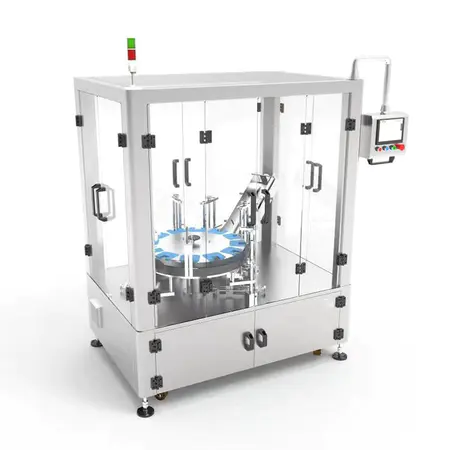

Advantages of Food Cartoning Machine

The advantages of using a food cartoning machine are significant. Firstly, these machines improve packaging efficiency, increasing production speeds and reducing labor costs. They provide consistent and precise cartoning, ensuring uniform packaging quality and a professional appearance of food products. Food cartoning machines contribute to product protection, preserving the freshness and integrity of food items. They also enhance branding and marketability, creating a visually appealing package that attracts consumers. Furthermore, these machines comply with food safety standards, ensuring hygienic packaging practices.

Types of Food Cartoning Machine

Food cartoning machines come in different types to cater to various packaging needs. Vertical cartoners are suitable for fragile food products that require gentle handling, such as delicate snacks or confectionery items. They form and load cartons in a vertical orientation. Horizontal cartoners, on the other hand, are ideal for larger and heavier food products. They form and load cartons in a horizontal orientation, providing stability and efficient packaging for items like cereal boxes or frozen food cartons.

Functions of Food Cartoning Machine

Food cartoning machines perform several essential functions. They start by forming cartons from flat blanks, either by folding or erecting them into the desired shape. The machine then loads food products into the formed cartons, either manually or automatically. This step may involve precise placement or orientation of the products within the cartons. Finally, the cartons are securely closed, typically using adhesives, tabs, or tuck-in flaps, ensuring the products remain safely contained.

Benefits of Food Cartoning Machine

A food cartoning machine offers several benefits in the packaging process. Firstly, it improves packaging efficiency by automating the cartoning process, reducing the need for manual labor and increasing production speeds. This leads to higher productivity and cost savings. The machine ensures consistent and precise carton formation, loading, and closure, resulting in uniform packaging quality and a professional presentation of food products. Additionally, food cartoning machines enhance product protection, preserving the freshness, integrity, and quality of food items during storage and transportation.

Frequently Asked Question

Do you have any question?

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging also refers to the process of designing, evaluating, and producing packages.

Plastics are used in many types of food packaging and containers for a variety of reasons – they help protect foods from damage, provides food safety and extends the freshness of foods.

Packaged food means food that has its entire surface covered in order to prevent direct contact of the food with the environment, either by permeable or impermeable wrapping. Sample 1.